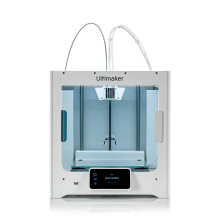

Image retrieved from Ultimaker's website

The Ultimaker S3s are provided for end-user use in the GVU Craft Lab. Please note the following rules with these machines:

- As always, please only use this equipment if you have received appropriate training on its use

- Please only use your own filament

- Please put your name on filament prior to print start to help ensure others do not mistake it for their own

- The lab will provide some limited amounts of PVA support material, but we request you limit use when possible

- When using PVA, please try to use the filament dryers for the material. If it is not possible to load material directly from the dryer, please let the filament dry out for approx. 30 minutes minimum before starting print. (This vastly increases chance of print success when using PVA)

Preparing Prints

Please use Ultimaker's Cura software to slice your STL and save the sliced print (.ufp) to a flash drive.

As noted above, we request you limit your use of lab-provided PVA support material as much as possible. This material is primarily intended for lab-affiliated projects but may be used for presentation-ready prototypes or for particularly complex parts. In general we ask that you try to use self-provided material (either breakaway or your own PVA) where possible. If you have any questions please reach out to lab staff.

Recommended Print Material

Below, please find a list of materials that have been tested on the GVU machines and appear to work well. This list is not exhaustive, but these materials generally yield quality results when prepared and printed appropriately. In general, the Ultimaker branded materials work well on the Ultimaker machines.

| Name | Notes | URL |

| Ultimaker PLA | https://ultimaker.com/materials/tough-pla | |

| MH Build Series PLA | https://www.matterhackers.com/store/l/magenta-pla-filament-3.00mm/sk/MF0SSEZH | |

| MatterHackers Quantum PLA | https://www.matterhackers.com/store/l/matterhackers-quantum-pla/sk/MS2XWRUN | |

| ColorFabb Woodfill* | Can become stringy and burn | https://colorfabb.com/woodfill |

| Ultimaker ABS* | Problems with print removal; let build plate cool fully before attempting | https://ultimaker.com/materials/abs |

* Materials marked with an asterisk (*) work, however they may require multiple prints to fine-tune print settings, bed adhesion, and print removal.

Reference Guides

Ultimaker has done a great job creating knowledge articles for their 3D printers so, rather than generate our own material, we recommend visiting the Ultimaker Knowledgebase for guides and videos on setting up 3D prints for the Ultimaker S3. https://support.ultimaker.com>